Hey Na+: Argonne National Lab Researchers Reach Breakthrough on Sodium Ion Battery Technology

Argonne National Laboratory researchers say they have enhanced sodium-ion batteries by preventing cracks in the cathode particles during the synthesis process, making what the researchers hope is a cost-effective and sustainable future alternative to lithium-ion batteries for electric vehicles and grid.

The increased demand of lithium-ion batteries, which current dominates the battery energy storage market, could lead to lithium supply shortages within the next five to 10 years.

“Sodium-ion batteries are emerging as a compelling alternative to lithium-ion batteries due to the greater abundance and lower cost of sodium,” said Gui-Liang Xu, a chemist at the U.S. Department of Energy’s (DOE) Argonne National Laboratory.

Sodium, noted by the chemical symbol Na (for the Latin ‘natrium’) is the sixth most abundant element in the Earth’s crust. Despite this, one of the roadblocks to commercializing sodium-ion (NA+) battery technology has been that the performance of the sodium-containing cathode declines with repeated discharge and charge.

Several years ago, researchers at Cornell discovered the cycling challenge within sodium ion energy storage.

For that reason, the Argonne National Lab team invented a new design for a sodium-ion oxide cathode, which is based on a previous design for a lithium-ion oxide cathode with high energy storage capacity and long life.

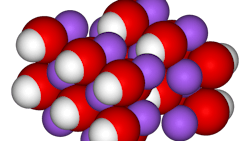

Microscopic cathode particles in both the designs include a mixture of transition metals like nickel, cobalt, iron or manganese. These metals are not uniformly distributed in individual cathode particles.

The team made two versions of hydroxide, a precursor material used to start the synthesis process. One with the metals distributed in a gradient from core to shell and another with the three metals evenly distributed throughout each particle, for comparison.

The team heated up a mixture of a precursor material and sodium hydroxide to 600 degrees Celsius, maintained it at that temperature for a selected period and then cooled it to room temperature to form the final product. They also studied different heat-up rates.

The team monitored the structural changes in the particle properties. This analysis involved use of two DOE Office of Science user facilities: the Advanced Photon Source (beamlines 17-BM and 11-ID) at Argonne and the National Synchrotron Light Source II (beamline 18-ID) at DOE’s Brookhaven National Laboratory.

The team also used the Center for Nanoscale Materials (CNM) at Argonne for additional analysis to characterize the particles and the Polaris supercomputer at the Argonne Leadership Computing Facility (ALCF) to reconstruct the X-ray data into detailed 3D images. The CNM and ALCF are also DOE Office of Science user facilities.

The initial results revealed no cracks in the uniform particles, but cracks forming in the gradient particles at 250 degrees C. These cracks appeared at the core and the core-shell boundary and moved to the surface, which revealed that the metal gradient caused strain leading to the cracks.

“Since we know that gradient particles can produce cathodes with high energy storage capacity, we wanted to find heat treatment conditions that will eliminate the cracks in the gradient particles,” said Wenhua Zuo, an Argonne postdoctoral appointee, in a statement.

While cracks formed at a heat-up rate of five degrees per minute, they were not at a slower rate of one degree per minute. Tests in small cells with cathode particles prepared at the slower rate maintained their high performance for over 400 cycles.

“Preventing cracks during cathode synthesis pays big dividends when the cathode is later charged and discharged,” said Gui-Liang Xu, a chemist at DOE’s Argonne National Laboratory. “And while sodium-ion batteries do not yet have sufficient energy density to power vehicles over long distances, they are ideal for urban driving.”

The team is working to eliminate the nickel from the cathode, which would reduce the cost even further and be more sustainable. Funding was provided by the DOE Vehicle Technologies Office, Office of Energy Efficiency and Renewable Energy, and Advanced Scientific Computing Research Program.