Supply Chain Energy Revolution: How to Secure Decarbonization All Down the Line

Businesses and governments across the globe have focused on investing in sustainability to provide energy security and increased uptime in all facets of business operations. Even though this has become the new status quo of how companies need to evolve, the world still finds itself falling short of meeting its net-zero goals by 2050.

To accomplish this, businesses must begin to decarbonize one of their most crucial operational assets – their supply chain.

The Lasting Effects of the Global Pandemic

In 2019 and 2020, the world was shocked by COVID-19, proving to have devastating effects which would last for years to come. To survive the storm, companies scrambled to acquire even the most basic of supplies to maintain some stability in manufacturing and production.

This mindset has lasted for years, but now, as this has started to abate and the supply chain has achieved a moderate level of certainty, it’s time for companies to reassess this as a real contributor to emissions and a tool to further achieve decarbonization goals.

While many are still rebuilding the supply chain network after the effects of the pandemic, they need to do so with sustainability at the forefront to ensure the world is growing and adapting in a way that helps reduce carbon emissions and contributes to a secure energy future.

“Supply chains are not only where the biggest risk for a company lies (because there is much we don’t have control over), but it’s also where most of the carbon emissions exist. Companies need to look at the supply chain transparency to manage not only compliance, product, and operational risks, but also carbon emission reduction strategies,” said Erika Peters, Senior Vice President at Exiger, in an exclusive interview with Energy Tech.

Emissions in the Supply Chain

“Over a year ago, we received the first formal questions around carbon emissions solutions in a request-for-proposal focused on Environmental, Social, and Governance risks. Other companies followed suit, asking about supply chain sustainability solutions, especially in Europe, which pushed our innovation team to help solve this part of Scope 3 emissions,” said Peters.

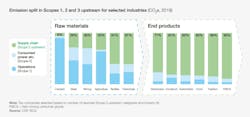

Scope 3 encompasses both upstream and downstream supply-chain processes that produce emissions. This includes the procurement of materials, the transportation of raw supplies and finished products, and product disposal.

According to research, eight supply chains account for over 50% of global Scope 3 greenhouse gas emissions. This includes:

- Food

- Construction

- Fashion

- Fast-moving consumer goods

- Electronics

- Automotive

- Professional services

- Freight

Although the culprits are well known, when asked why more measures haven’t been taken to decarbonize these supply chain processes, Peters responded, “When we asked the suppliers themselves, many suppliers weren’t tracking or didn’t understand what Scope 3 emissions were. Supply chain emissions are very difficult to capture data on, and it takes a lot of time to do.”

Partnering with Suppliers to Build Sustainability Together

A company’s supply chain is crucial to its success and ability to provide its core products to ultimate consumers. Yet, the intricacies of maintaining a supply chain are often overlooked, and the burden of responsibility falls to the supplier, who either shows little interest in sustainable evolution due to a lack of outside motivation or is too overwhelmed to undertake energy transition measures alone.

This is where companies must be proactive and partner with their suppliers to discover what changes need to be made and find an equitable solution favorable for both parties.

“Companies need to find the big wins by looking at the suppliers they are engaging with the most and discovering how they can help reduce the supplier’s carbon emissions. Companies have a great deal of leverage through the contracts they make with suppliers.

“For example, you could tell your suppliers you will send them more work, but instead of focusing solely on a buying program to reduce costs, you could also include a measure to continue or expand business with them in exchange for the supplier taking steps to reduce their carbon emissions. This creates a cyclical win-win for everybody involved,” said Peters.

How to Reduce Scope 3 Emissions in the Supply Chain

Even though data on Scope 3 emissions is often difficult to attain, once a partnership is formed, companies can help suppliers take the right steps to ensure they are advancing towards decarbonization goals and fulfilling their end of the contract.

According to the World Economic Forum, there are several factors that a supplier can focus on to reduce their overall Scope 3 emissions with minimal effect on the end-consumer cost.

This includes:

- Increasing their use of recycled materials.

- Improving production efficiency to reduce product waste and power usage, including introducing or switching to new production processes.

- Switching to renewable energy, such as solar and wind.

- Replacing coal and gas for industrial heat and steam generation with electricity powered by renewable energy.

- Utilizing carbon capture and storage technologies to capture unavoidable carbon emissions generated during the production process.

By applying these simple measures, a supplier can abate around 40% of all production emissions with only a 1-4% increase in end-consumer costs in the medium term.

Not only will these upgraded processes create a more sustainable supply chain network, but they can also have a positive impact on the retail side. According to research, more than 50% of consumers – especially those in Western countries – are willing to pay more for products produced using sustainable methods.

This can ultimately help companies and suppliers cover any additional costs incurred from switching to more sustainable practices and technologies.

However, when companies begin having these conversations with their suppliers, they must also be conscientious of the suppliers' immediate geographical and economic situation.

“You need to understand your suppliers from a risk perspective first to see if you should work with them before investing in their sustainability efforts and continue to do business while staying true to your company’s core values.

“Subsequently, you should understand what materials and energy suppliers have access to, focusing strategies on companies who could reduce carbon emissions easier than others. We need to assess the suppliers and their value chains to get a baseline and build in opportunity scores, helping to make decisions and take actions quickly to create real change,” said Peters.

The Movement Has Already Started

These necessary conversations have already started across multiple sectors and industries. By bringing this conversation to the forefront of business dealings, especially in larger companies with the capital and conditions to achieve results quickly, a path forward can be paved, and a new business model that centers around improved sustainability and increased efficiency can be created.

“Larger corporations need to lead the way – they are the ones who can make the biggest impact because they are the ones who are polluting the world the most. But, by helping growing companies understand the focus on Scope 3 emissions, we can create a trickle-down effect. The companies that take action first will set themselves apart from the competition, and soon, other companies will model after these innovative groups.

“But this is just the starting point. Eventually, whole countries will begin to make the shift, especially in proactive locations. And once other countries realize this is where supplier investments are made, they will begin to shift their infrastructure and sustainable options for energy and materials as well.

“It has been slow moving in the past, but there is more transparency within the industry, and this is the right time to invest in supply chain decarbonization,” concluded Peters.

About the Expert

Erika Peters, a Senior Vice President, is Exiger’s Lead in ESG Client Engagements. Additionally, she serves as the Global Head of Innovation & Operations for Exiger’s commercial business, spearheading innovation and driving the ongoing enhancement of scalable, cutting-edge AI solutions to meet the dynamic demands of the commercial market.

With a career spanning two decades, Erika leads a global team dedicated to serving the organization’s most prominent clients. Her expertise encompasses consulting, compliance, regulatory affairs, and internal audit.

Before joining Exiger, Erika contributed her valuable insights and skills at renowned institutions such as American Express and Deutsche Bank.